GS 10

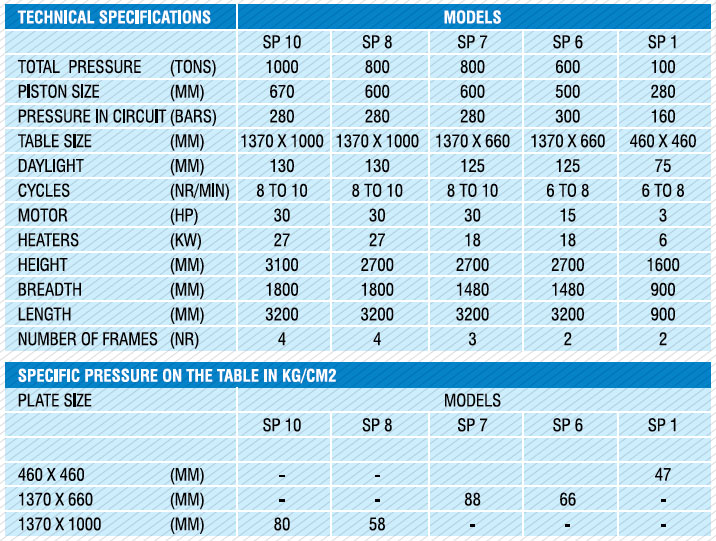

This is the heaviest machine which we have made so for. We have made two such machine and both of them are running with Tata International Ltd, Dewas. This gives you the advantage of speed, bigger table size and higher pressure, that of 1000 Tons. This is again a four pillar type design. We have made a very heavy rising table as well in this model so that one can achieve very good embossing results. It one is making buffalo or cow with deep design prints, this model is best suited. This model has a table size of 1370mm x 1000mm. The maximum capacity is 1000 Tons. It is fitted with a 40 HP motor along with a piston pump.

The structure of the machine is a completely modular one. The top and bottom blocks are manufactured by thick steel plates electrically welded together to form hollow box girders which provide perfect structural rigidity. They are then baked in a furnace to remove any stresses in the structure and then machined to provide accurate results. The top and bottom blocks are held together by four robust forged steel pillars which again help in maintaining accuracy in the structure. From decades, all the top manufacturers in the world have used this tried and tested pillar type design.

The pressure is provided by means of a single cylinder which is made of forged steel and is transmitted to a thick and heavy table for uniform distribution of working pressure. Sizes of working table can be either 1370 x 1000 mm or 1500 x 1000 mm. The safety device provides protection against accidents and trouble free operation. The working parameters – temperature of the table, pressure exerted on the hide, time of pressure are all easily adjustable. It is also possible to set the repetition of strokes. The table is electrically heated. The heaters are divided into 3 segments. Each segment is controlled separately from the others providing a uniform distribution of heat on the entire surface. The high flow pump is dynamically controlled to reduce the power consumption. The electrical control panel is simple and easy to maintain yet providing all the necessary functionality.

SP 6

This is one the most popular models which we manufacture. It is having a standard table size of 1370mm x 660mm (54 inched x 26 inches). The maximum pressure it can exert is 600 Tons. It is fitted with a 15 HP motor coupled with a piston pump. This is a pillar type machine wherein the top and bottom blocks are fabricated separately and held together by two thick and robust pillars. Safety guards come as a standard feature in it.

The structure of the machine is a completely modular one. The top and bottom blocks are manufactured by thick steel plates electrically welded together to form hollow box girders which provide perfect structural rigidity. They are then baked in a furnace to remove any stresses in the structure and then machined to provide accurate results. The top and bottom blocks are held together by four robust forged steel pillars which again help in maintaining accuracy in the structure. From decades, all the top manufacturers in the world have used this tried and tested pillar type design.

The pressure is provided by means of a single cylinder which is made of forged steel and is transmitted to a thick and heavy table for uniform distribution of working pressure.

Sizes of working table can be either 1370 x 1000mm.

The safety device provides protection against accidents and trouble free operation.

The working parameters – temperature of the table, pressure exerted on the hide, time of pressure are all easily adjustable.

The table is electrically heated.

The electrical control panel is simple and easy to maintain yet providing all the necessary functionality.

SP 8

This model is best suited for goat and sheep leather. This has a bigger table size 1370mm x 1000mm. It is also a pillar type design. It is built in four pillars. The maximum pressure it can generate is 800 Tons. Because of its bigger table size, the entire sheep or goat hide can be printed in one stroke. There are no overlapping marks too. As a result productivity and quality is enhanced. This model is very popular in southern India as most of the people do sheep and goat.

The structure of the machine is a completely modular one. The top and bottom blocks are manufactured by thick steel plates electrically welded together to form hollow box girders which provide perfect structural rigidity. They are then baked in a furnace to remove any stresses in the structure and then machined to provide accurate results. The top and bottom blocks are held together by four robust forged steel pillars which again help in maintaining accuracy in the structure. From decades, all the top manufacturers in the world have used this tried and tested pillar type design.

The pressure is provided by means of a single cylinder which is made of forged steel and is transmitted to a thick and heavy table for uniform distribution of working pressure.

Sizes of working table can be either 1370 x 1000mm.

The safety device provides protection against accidents and trouble free operation.

The working parameters – temperature of the table, pressure exerted on the hide, time of pressure are all easily adjustable.

The table is electrically heated.

The electrical control panel is simple and easy to maintain yet providing all the necessary functionality.

SP 7

This is our latest product. This is a high speed machine which can complete one cycle in about 5 – 6 secs. It has all the features of GS 6. The maximum capacity is 800 Tons. The table size is 1370mm x 660mm (54 inched x 26 inches). It is fitted with a 30 HP motor coupled with a piston pump. The major advantage of this model is its speed and higher -pressure. Due to this, it can give a good productivity with the same resources.

This is the latest machine which we have manufactured. The advantage of this machine is its high speed of lifting and pressure build up speed. You can also repeat a stroke without the table coming down for superior embossing results. Please see the videos for a better understanding.

The structure of the machine is a completely modular one. The top and bottom blocks are manufactured by thick steel plates electrically welded together to form hollow box girders which provide perfect structural rigidity. They are then baked in a furnace to remove any stresses in the structure and then machined to provide accurate results. The top and bottom blocks are held together by four robust forged steel pillars which again help in maintaining accuracy in the structure. From decades, all the top manufacturers tec in the world have used this tried and tested pillar type design.

The pressure is provided by means of a single cylinder which is made of forged steel and is transmitted to a thick and heavy table for uniform distribution of working pressure.

Sizes of working table can be either 1370 x 660mm.

The safety device provides protection against accidents and trouble free operation.

The working parameters – temperature of the table, pressure exerted on the hide, time of pressure are all easily adjustable. It is also possible to set the repetition of strokes.

The table is electrically heated. The heaters are divided into 3 segments. Each segment is controlled separately from the others providing a uniform distribution of heat on the entire surface.

The high flow pump is dynamically controlled to reduce the power consumption.

The electrical control panel is simple and easy to maintain yet providing all the necessary functionality.

SP 1

SP1 – H Type

This machine is also used for making leather components. It has a relatively smaller table size (18 inches x 18 inches) and can print only small hides. This machine comes in two variants: C type and H Type. The H type variant is having an "eject out table" mechanism. One can place the samples on the table very easily. The maximum pressure it can exert on the table is 100 Tons. It is a completely built unit. The entire power pack of the machine is within the frame of the press. It is fitted with a 3 HP motor coupled with a gear pump which gives a soundless operation. We have installed 6 heaters of 700 Watts each to heat the embossing plate.

This machine is also used for making leather components. It has a relatively smaller table size (18 inches x 18 inches) and can print only small hides. This machine comes in two variants: C type and H Type. The H type variant is having an "eject out table" mechanism. One can place the samples on the table very easily. The maximum pressure it can exert on the table is 100 Tons. It is a completely built unit. The entire power pack of the machine is within the frame of the press. It is fitted with a 3 HP motor coupled with a gear pump which gives a soundless operation. We have installed 6 heaters of 700 Watts each to heat the embossing plate.

SP1 – C Type

This machine is used for making leather components. It has a relatively smaller table size (18 inches x 18 inches) and can print only small hides. This machine comes in two variants: C type and H Type. This variant has three sides open. One can even print logos on large hides by simply holding the hide as the table rises to emboss. The maximum pressure it can exert on the table is 100 Tons. It is a completely built unit. The entire power pack of the machine is within the frame of the press. It is fitted with a 3 HP motor coupled with a gear pump which gives a soundless operation. We have installed 6 heaters of 700 Watts each to heat the embossing plate

This machine is used for making leather components. It has a relatively smaller table size (18 inches x 18 inches) and can print only small hides. This machine comes in two variants: C type and H Type. This variant has three sides open. One can even print logos on large hides by simply holding the hide as the table rises to emboss. The maximum pressure it can exert on the table is 100 Tons. It is a completely built unit. The entire power pack of the machine is within the frame of the press. It is fitted with a 3 HP motor coupled with a gear pump which gives a soundless operation. We have installed 6 heaters of 700 Watts each to heat the embossing plate.